Industrial Injection-Molding-Grade 3D Printing Solution for Smart Mass Production Leading a New Industry Transformation

2025/08/04

Abstract: As the manufacturing sector is constantly seeking breakthroughs and innovation, every new technology has the potential to reshape the industry landscape.

It is widely known that, despite being a high-precision technology in 3D printing, resin 3D printing has not been able to fully replace injection molding. The main bottleneck lies in the fact that the printed parts often struggle to meet the structural strength and physical performance requirements for industrial applications, limiting their use to prototype verification and other testing phases. Now, with the stunning launch of Flashforge's R Series 3D printers, this situation is about to be completely rewritten!

On April 16, Flashforge, a global leader in 3D printing, officially unveiled its brand-new industrial injection-molding-grade 3D printers, the R Series (R1/R1 MAX), along with its solutions.

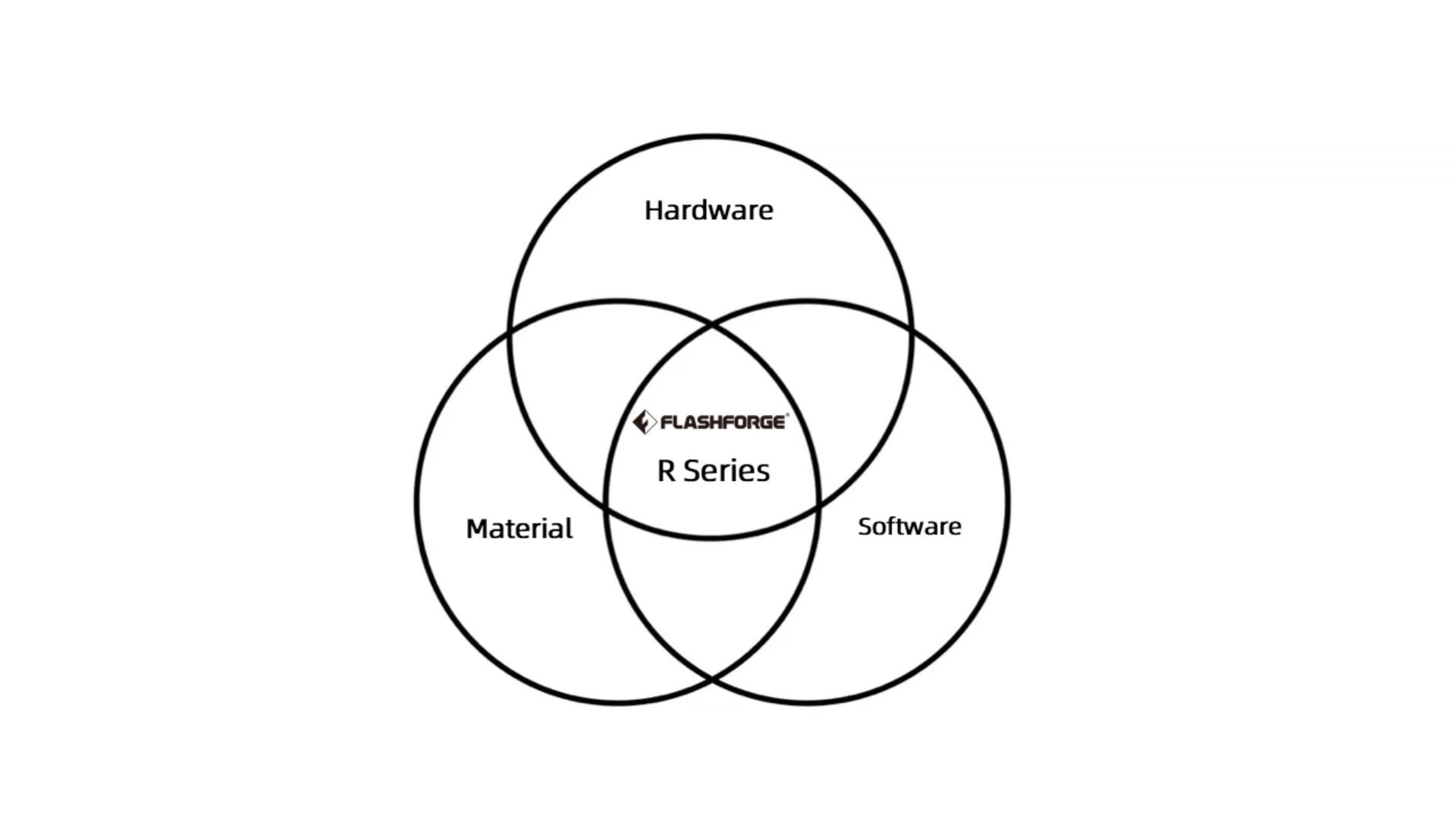

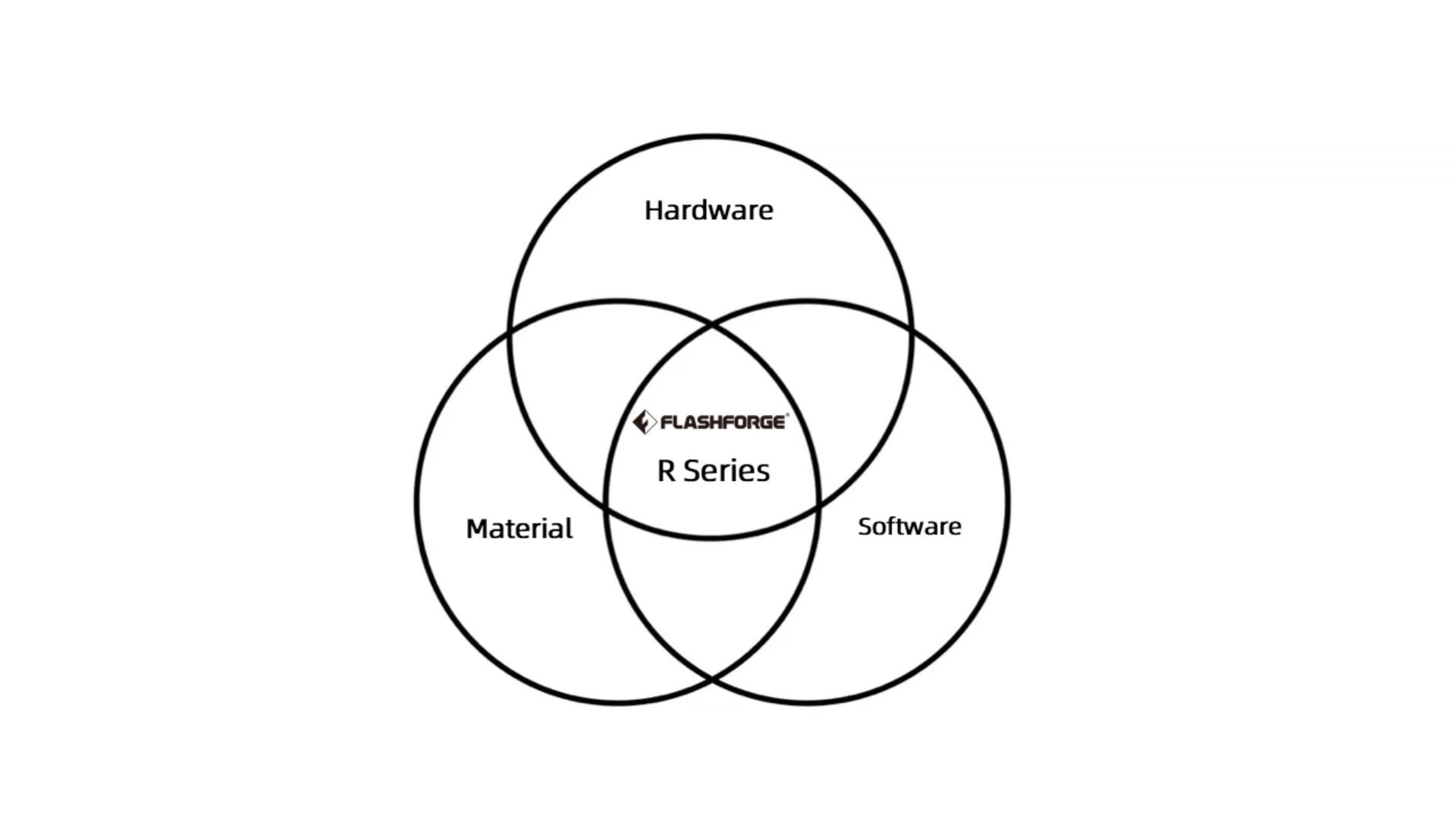

Powered by DLP (Digital Light Processing) technology and Flashforge's self-developed PReS (Photon Reaction System), this cutting-edge lineup integrates industrial-grade hardware, high-performance polymer materials, and cloud-based intelligent control software. Together, they deliver a complete, mold-free photon-based smart mass production solution for the manufacturing industry.

Traditional injection molding often faces the challenges of long mold development cycles and high costs, which significantly limit rapid product iteration and customization.

The R Series industrial injection-molding-grade 3D printing solution for smart mass production, integrating hardware, materials, and software, is currently the most comprehensive photon-based additive manufacturing solution available on the market. It replaces traditional injection molding with a digital workflow, enabling efficient production of components with excellent mechanical properties and surface finishes comparable to injection molding quality.

Meanwhile, the R-series can flawlessly produce both complex structures and highly precise parts with tight tolerances, achieving an accuracy of ±65μm. This ensures that every product meets strict industrial standards and fills the market gap in realizing the concept of "Prototypes Ready for Mass Production".

It can be widely applied to scenarios such as engineering prototype production and small-to-medium batch production of high-performance resin end-use products.

R Series: World's Leading Industrial Injection-Molding-Grade 3D Printer

R1 and R1 MAX offer larger build volumes for printing large parts as well as smaller components.

A four-axis gantry structure ensures precise, multi-dimensional positioning of parts even during high-speed printing, which boosts both accuracy and yield. A multi-modal sensor cluster composed of over 20 sensors provides complete control and traceability for every step of the printing process. Combined with the industrial PC dynamic process, it can successfully sense, analyze and dynamically adjust process parameters in real time, achieving an efficient, flexible and high-precision automated manufacturing process.

This advanced product design philosophy, coupled with Flashforge's over a decade of accumulated manufacturing expertise, provides reliable guarantees for injection-molding-grade quality and flawless end-use part production.

Extensive & Diverse Materials: Versatile for Multiple Scenarios and Wide-Range Applications

Flashforge has built a comprehensive industrial-grade 3D printing material library to meet the manufacturing needs of end-use applications across various scenarios. The finished parts boast excellent mechanical properties comparable to those of traditional thermoplastics.

Currently, there are over 20 types of materials available, including ABS-like, nylon-like, PEEK-like, and elastomers. The finished parts exhibit superior mechanical properties and surface finishes, making them suitable for direct use in products like consumer electronics, humanoid robots, and automobiles.

This allows for unrestricted design and rapid product iteration, helping the manufacturing industry take a further step toward flexible manufacturing.

Intelligent Digital Cloud Hub, Collaborative Software Ecosystem

The R Series solutions also come with supporting software FlashReady2 and Cloud Management Platform, which bridge the data flow from design to manufacturing, ensuring every print task is efficiently prepared and production decisions are data-driven.

FlashReady2 provides users with intelligent layout suggestions and one-click support generation. This software integrates exclusive print templates for each material and end application, supports smart pre-print checks for critical model parameters, offers real-time alerts for potential print risks, and provides optimization suggestions. This ensures efficient slicing for every material, delivering optimal print results—ready to use right out of the box.

The Cloud Management Platform, deeply integrated with FlashReady2, builds a closed-loop ecosystem spanning "model processing - task scheduling - device management - data insight", enabling simultaneous improvements in 3D printing production efficiency and data value.

3D Printing, Built Like It's Molded

"3D Printing, Built Like It's Molded" has long been the goal for Flashforge's DLP team, and it is also the key reason why customers choose to partner with us.

By enabling mass-produced 3D printed products to achieve the production quality of injection molding, we help businesses bypass the lengthy, cumbersome and time-consuming process chains of traditional production. This empowers our enterprise clients to accelerate product iteration, speed up delivery, improve market responsiveness, and ultimately enhance their competitive edge—all while reducing production costs.

In the future, Flashforge's DLP team will continue to focus on end-use applications. We will develop more diversified materials to meet the needs of various scenarios and enable mass production across multiple sectors, including automotive, consumer electronics, and sports & health.

SUBSCRIBE TO US

Be the first to receive our latest updates

Copyright© 2012-2025 Flashforge All Rights Reserved.

Copyright of Flash Casting Group浙ICP备19026245号-1